MaintBoard CMMS Software

CMMS Software

Modern CMMS software for plants and facilities

MaintBoard is a CMMS software that helps maintenance teams plan work, manage assets, and maintain clear maintenance records across industrial operations.

What You Can Manage

- Preventive and breakdown maintenance

- Assets, locations, and equipment history

- Work orders, inspections, and checklists

- Maintenance records and performance reports

Why Teams Move to CMMS Software

- Maintenance tracked in Excel

- Spreadsheets make it hard to track history, accountability, and progress.

- Frequent breakdowns

- Lack of preventive planning leads to unplanned downtime.

- No asset history

- Teams cannot see past failures, repairs, or costs.

- Manual audit preparation

- Maintenance records are scattered across files and folders.

Where CMMS Software Is Used

MaintBoard CMMS is used across industrial and facility environments to manage maintenance operations.

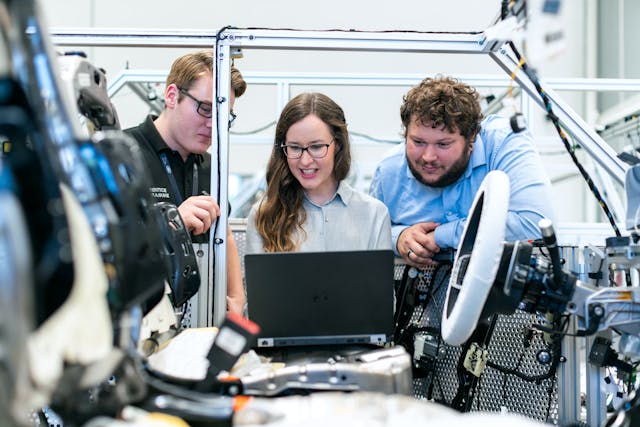

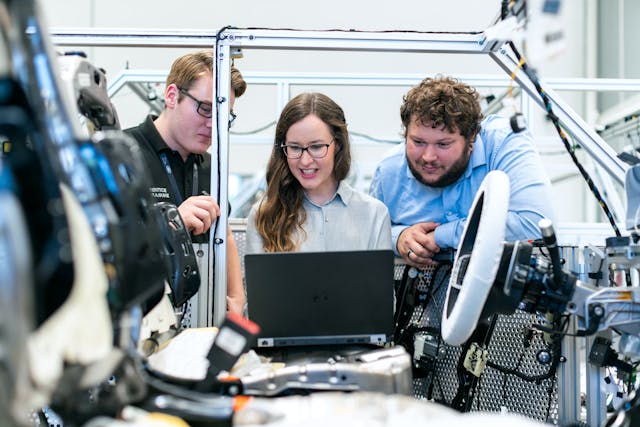

- Manufacturing Plants

- Manage machines, production lines, utilities, and support equipment.

- Facilities & Buildings

- Maintain HVAC, electrical, plumbing, and infrastructure assets.

- Process Industries

- Track pumps, compressors, reactors, and continuous process equipment.

- Quality & Compliance Teams

- Maintain inspection records, PM logs, and maintenance traceability.

Features

Everything You Need in a CMMS

MaintBoard combines essential maintenance capabilities in one system.

- Work Order Management

Plan, assign, execute, and close maintenance work orders.

- Preventive Maintenance

Schedule PMs by time, usage, or condition.

- Asset Management

Maintain asset hierarchy, criticality, and full history.

- Spare Parts & Inventory

Track spares, stock levels, and part usage.

- Reports & Analytics

Monitor downtime, compliance, and maintenance KPIs.

Metrics

What Teams Achieve With CMMS

Organizations using CMMS software report measurable improvements.

20–40%

Reduction in unplanned downtime

Better planning and faster response.

Higher

PM compliance

Scheduled maintenance completed on time.

Clear

Maintenance visibility

Complete asset and work order history.

CMMS Software FAQs

- What is CMMS software?

- CMMS software helps maintenance teams plan, track, and manage maintenance work and assets digitally.

- Who should use CMMS software?

- Maintenance technicians, planners, supervisors, and managers.

- Can CMMS replace Excel?

- Yes. CMMS provides structure, traceability, and real-time visibility beyond spreadsheets.

- Is CMMS suitable for manufacturing?

- Yes. CMMS is widely used in manufacturing, facilities, and process industries.

Move From Spreadsheets to CMMS

Organize maintenance work, reduce downtime, and gain visibility with MaintBoard.