Energy Meter CMMS Integration: Boost Uptime and Cut Costs

Introduction

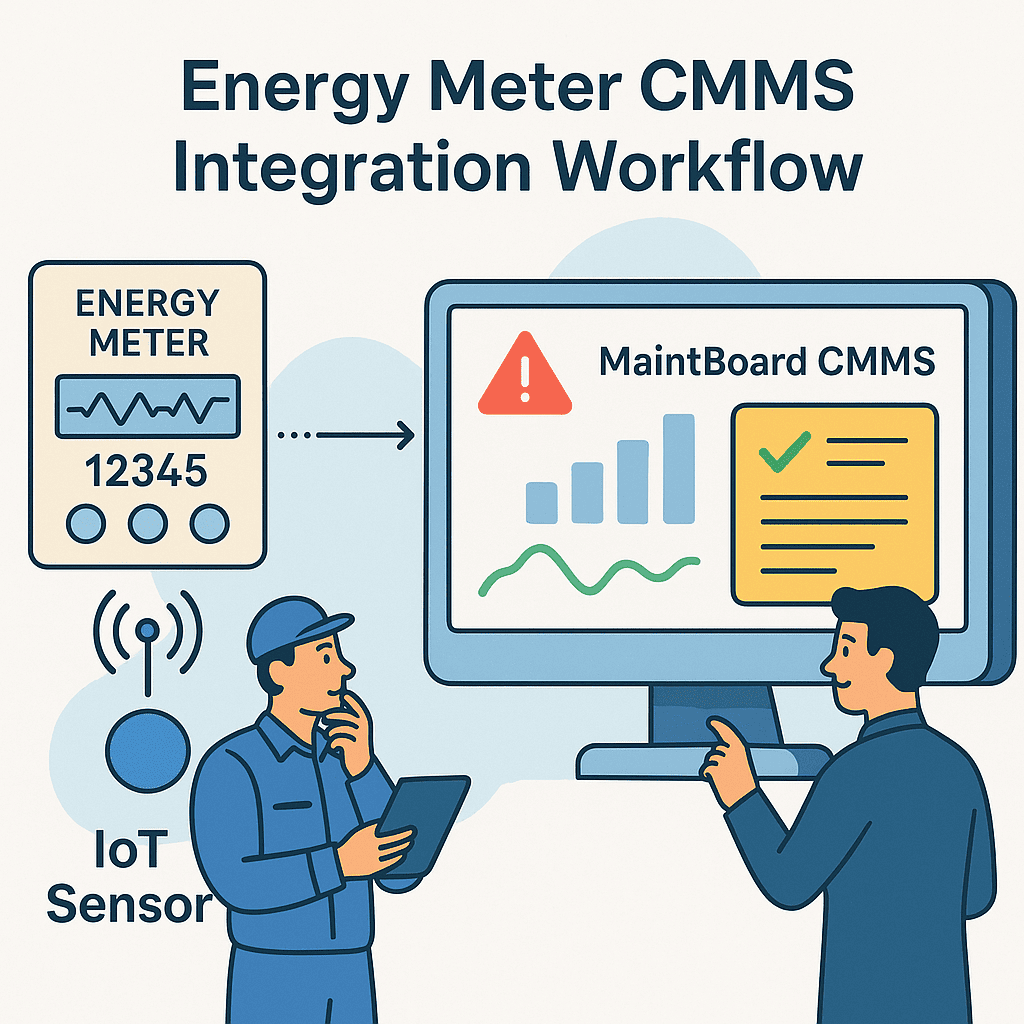

Want to reduce downtime and energy waste? See why more maintenance leaders are integrating energy meters with their CMMS systems: Read the full energy monitoring guide.

Energy meter CMMS integration is no longer a nice-to-have—it’s essential for maintenance teams looking to align reliability, sustainability, and cost-efficiency. In many industrial facilities, energy anomalies are early warning signs of asset failure. But without integration, those insights never reach the people responsible for fixing the issue.

This guide walks you through how to implement energy meter CMMS integration, key technologies, and real use cases to bring your maintenance strategy into 2025.

1. Why Energy Meter CMMS Integration Matters

Integrating energy meters with your CMMS enables:

- Real-time detection of energy anomalies

- Condition-based preventive maintenance (based on kWh, temperature, etc.)

- Energy cost tracking at the asset or department level

- Data-backed justification for upgrades and maintenance budgets

- Reduction in unnecessary PMs by using actual consumption trends

- Better sustainability metrics and reporting

When done right, energy meter CMMS integration leads to both operational savings and improved asset uptime. It also gives maintenance teams a direct hand in energy conservation strategies.

2. Common Types of Energy Meters You Can Integrate

- Electrical meters: Monitor voltage, amperage, and energy (kWh)

- Thermal meters: Monitor hot water, chilled water, or steam usage

- Gas & compressed air meters: Capture leaks or overconsumption

- IoT-enabled sensors: Stream real-time data over protocols like MQTT or Modbus

These meters typically communicate with industrial gateways or building management systems (BMS), which can then relay the data to your CMMS via API.

3. Key Components Required for Integration

To achieve energy meter CMMS integration, your setup should include:

- A modern CMMS (cloud-based or with an open API)

- Network-connected meters or IoT sensors

- Edge computing or middleware (like Node-RED or Kepware)

- Mapped relationship between asset IDs and meter IDs

- Support from OT/IT for data routing and timestamping

Starting with high-energy equipment like chillers, compressors, or pumps is usually the most impactful.

4. How Energy Data Flows into the CMMS

- Meters collect asset-level data continuously

- Data is cleaned and normalized via middleware

- CMMS receives data through API/webhook endpoint

- Rules or thresholds trigger alerts, logs, or work orders

For example, a spike in kWh may trigger a work order titled: “Check Motor Bearings – High Power Consumption Detected”.

You can also visualize this data on CMMS dashboards alongside failure history or downtime logs for a more complete picture.

5. Real-World Use Cases for Energy Meter CMMS Integration

- Air compressor leak detection: Sudden rise in consumption triggers leak inspection work order

- Cooling tower monitoring: Higher energy draw than baseline triggers coil cleaning

- Predictive maintenance: Motor kWh usage increases steadily—PM triggered before breakdown

- Energy efficiency auditing: CMMS logs overconsumption events tied to specific assets

- Utility cost allocation: Facilities can analyze energy use by asset or line to budget more accurately

- Carbon reporting alignment: Energy data tied to specific assets can contribute to Scope 1 & 2 emission tracking

6. Challenges and How to Solve Them

- Data noise: Set thresholds to ignore insignificant fluctuations

- Timestamp mismatches: Use synchronized time servers for CMMS and meters

- False positives: Always compare against established asset baselines

- Change management: Train technicians on how to interpret and respond to energy-triggered work orders

Also, make sure your data privacy and access protocols align with your organization’s cybersecurity policies.

7. Who Should Lead the Integration Project?

A successful energy meter CMMS integration often requires collaboration between departments. Ideally, a cross-functional team should be formed with:

- Maintenance Manager: Defines use cases, alert thresholds, and asset linkage.

- Energy Manager or Facilities Engineer: Oversees energy strategy and verifies meter placement and calibration.

- IT/OT Lead: Ensures secure and continuous data flow between systems.

- CMMS Administrator: Manages rule configurations, workflow automation, and dashboard visibility.

Having clear ownership across these roles helps avoid silos and ensures the system delivers real operational impact.

8. Best Practices for Long-Term Success

- Conduct monthly reviews of energy trend data linked to assets

- Regularly recalibrate meters and validate threshold settings

- Use CMMS dashboards to visualize savings from energy-based PMs

- Create SOPs for technicians to respond consistently to energy alerts

- Capture case studies and ROI data to report progress to leadership

These best practices help sustain adoption, improve data reliability, and increase the strategic value of your CMMS integration.

9. Common Questions from Maintenance Leaders

Here are some frequently asked questions from engineering and operations leaders considering energy meter CMMS integration:

How much data history should we keep?

Ideally 12–24 months to establish asset baselines and seasonal consumption trends.

Can we integrate existing meters or do we need new hardware?

If your meters support Modbus, MQTT, OPC UA, or BACnet, you can often integrate them via middleware or edge gateways.

What is the ROI timeframe?

Most plants see ROI within 6–12 months through energy savings, reduced breakdowns, and better PM targeting.

Do we need a full-time person to manage this integration?

No. Once integrated, the system can run largely in the background with alerts and dashboards. Admin time is minimal.

These insights help decision-makers prepare for deployment and ensure expectations are grounded in real use cases.

Conclusion: Turn Energy Signals into Action

Energy meter CMMS integration empowers your maintenance team to detect problems earlier, act faster, and cut waste. By combining asset performance and energy behavior, you unlock predictive power that reactive maintenance simply can’t offer.

It also supports energy savings initiatives, regulatory compliance, and long-term asset optimization.

Want to learn how MaintBoard integrates real-time energy data into your maintenance workflows? Schedule a walkthrough or talk to our team.