WHO PQS Cold Chain Guide: 6 Keys to Safe Vaccine Storage

Introduction: Why WHO PQS Cold Chain Compliance Matters

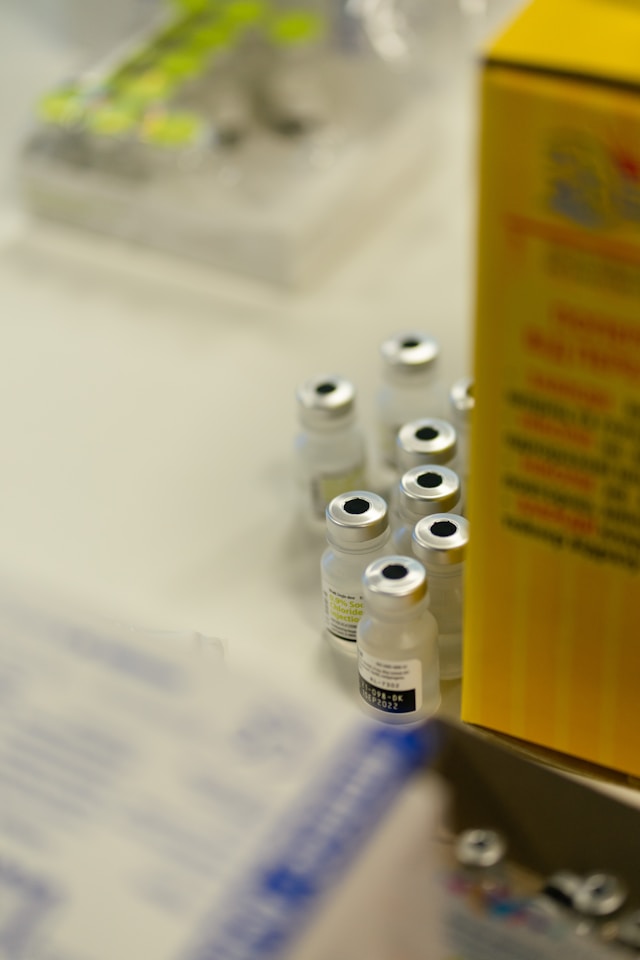

WHO PQS cold chain compliance is essential for safe and effective vaccine distribution. Whether you run a national immunization program or a private facility, maintaining a reliable cold chain helps protect public health — and builds trust in your operations.

The World Health Organization’s Performance, Quality, and Safety (PQS) standards define the minimum criteria for vaccine storage equipment. But being compliant isn’t just about installing PQS-approved freezers and fridges — it’s also about maintaining them, monitoring performance, and being audit-ready.

This guide breaks down what WHO PQS compliance really means and shows how to manage your cold chain the right way.

1. What Is WHO PQS Cold Chain Compliance?

WHO PQS cold chain compliance means using equipment that meets WHO’s approved performance standards — and maintaining it according to best practices. Approved cold chain equipment includes:

- Vaccine refrigerators and freezers

- Cold boxes and vaccine carriers

- Digital temperature monitoring devices

- Solar-powered direct-drive cold rooms

This compliance is mandatory for UN and Gavi-funded programs, and widely adopted by private providers who want to meet global quality benchmarks.

2. Why It’s Critical to Follow PQS Standards

Here’s why WHO PQS compliance is non-negotiable:

- ✅ Keeps vaccines within the safe 2–8°C range

- ✅ Reduces risks of spoilage or temperature excursions

- ✅ Helps you qualify for global immunization initiatives

- ✅ Strengthens trust among stakeholders, partners, and end-users

But compliance isn’t just about the equipment — it’s about the processes that support it.

3. Key Maintenance Tasks for PQS Equipment

To maintain a WHO PQS cold chain, your team should regularly perform the following tasks:

| Task | Frequency | Why It Matters |

|---|---|---|

| Record min/max temperatures | Daily | Catch fluctuations early and keep reliable logs |

| Inspect seals, fans, doors | Weekly | Prevent air leaks and uneven cooling |

| Test alarms and backup systems | Monthly | Ensure alerts trigger correctly |

| Calibrate sensors & loggers | Quarterly | Maintain temperature accuracy |

| Clean condenser coils/filters | Monthly | Improve energy use and performance |

Regular maintenance keeps your cold chain resilient and audit-ready.

4. Documentation for WHO PQS Cold Chain Compliance

Proper documentation is key to passing inspections. You should have:

- Daily temperature monitoring logs

- Maintenance and calibration records

- Service and installation logs

- Alarm event reports

- Validation and commissioning files

Digital storage of these documents helps with traceability and simplifies audits.

5. How a CMMS Helps Maintain WHO PQS Compliance

A CMMS (Computerized Maintenance Management System) like MaintBoard simplifies cold chain management by:

- Automating maintenance scheduling

- Digitally recording every task and calibration

- Storing temperature logs, sensor data, and maintenance files in one place

- Generating PQS audit-ready reports with one click

- Tracking downtime, alarm responses, and corrective actions

This reduces manual error, increases accountability, and boosts long-term cold chain performance.

Frequently Asked Questions (FAQ)

What is WHO PQS cold chain compliance?

WHO PQS cold chain compliance means using equipment that meets the World Health Organization’s PQS standards and maintaining it through regular monitoring, calibration, and documentation. This ensures vaccines stay within the safe temperature range of 2–8°C.

Why is PQS compliance important for vaccine storage?

PQS compliance is crucial because it ensures vaccines are stored at the correct temperature, reducing the risk of spoilage and ensuring public safety. It also helps facilities meet international health regulations and qualify for funding programs like Gavi.

Is WHO PQS compliance required for private cold chain providers?

While not legally required for all private providers, WHO PQS compliance is widely adopted by private healthcare and logistics companies to meet global standards and ensure trust in their vaccine handling processes.

How does a CMMS help with WHO PQS compliance?

A CMMS (Computerized Maintenance Management System) helps automate preventive maintenance, store temperature logs, track equipment calibration, and generate audit-ready reports. It streamlines compliance and reduces the risk of human error.

Can WHO PQS cold chain compliance improve audit readiness?

Yes. Maintaining detailed digital records of maintenance, temperature logs, and alarm responses ensures your cold chain system is always prepared for audits and inspections, both internal and external.

What’s the difference between WHO PQS and GMP compliance?

WHO PQS focuses specifically on the performance and maintenance of vaccine cold chain equipment. GMP (Good Manufacturing Practice) is broader and applies to the production, storage, and handling of all pharmaceutical products.

Conclusion: Be Ready. Be Compliant. Be Trusted.

Following the WHO PQS cold chain standard isn’t just a regulatory box to check — it’s a commitment to vaccine safety. By maintaining your equipment properly and documenting every step, you keep your cold chain strong and resilient.

Tools like MaintBoard’s CMMS make the process easier, more consistent, and fully auditable — so every vaccine reaches the people who need it, at the right temperature, every time.

👉 Book a demo of MaintBoard or Download our free WHO PQS Maintenance Checklist (coming soon) to get started.