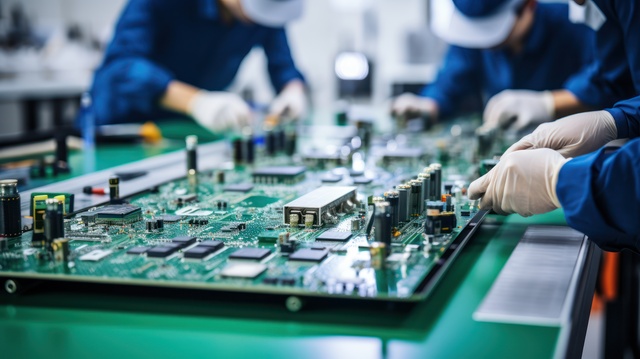

MaintBoard for Electronics Manufacturing

CMMS for Electronics, PCB & Semiconductor Plants

Improve uptime across SMT, PCB assembly, testing, and cleanroom operations.

MaintBoard helps electronics manufacturers prevent breakdowns, strengthen process control, and maintain maximum uptime across SMT lines, reflow ovens, conveyors, testing equipment, and cleanroom utilities.

Key Benefits

- Reduce stoppages on SMT, reflow, wave solder, and conveyors

- Digitize inspections, calibration, and critical equipment PMs

- Strengthen traceability for ISO, IATF, and customer audits

- Prevent recurring failures with centralized RCA and history

Maintenance Challenges in Electronics Manufacturing

- Frequent SMT Line Stoppages

- Pick-and-place heads, feeders, vision systems, and conveyors fail due to dust, misalignment, or lubrication gaps.

- Reflow Oven & Wave Solder Issues

- Temperature fluctuations, heater failures, and flux buildup cause quality defects and downtime.

- Poor Calibration Tracking

- Testing benches, AOI machines, and measurement tools require strict calibration discipline.

- Weak Spare Parts Visibility

- No real-time tracking for nozzles, belts, sensors, feeders, motors, heaters, and instrumentation.

- Limited Visibility Into Repeat Failures

- Without RCA and history, troubleshooting SMT or AOI issues is slow and inconsistent.

- Cleanroom & EHS Compliance Pressure

- Plants must maintain HVAC, filtration, temperature, humidity, and ESD compliance for audits.

Workflow

How MaintBoard Strengthens Plant Reliability

MaintBoard centralizes SMT, equipment, utilities, calibration, and factory-wide maintenance into one real-time system.

- Digitize Inspection Rounds

- Create mobile checklists for SMT feeders, pick heads, conveyors, ovens, vacuum pumps, compressors, and utilities.

- Complete Equipment History

- Access failures, spares used, downtime records, and repair notes in one place.

- Automate PM Schedules

- Lubrication, cleaning, calibration, alignment, and filter changes—done on time, every time.

- Attach Manuals, Layouts, & SOPs

- Upload SMT manuals, electrical diagrams, SOPs, ESD documents, and calibration certificates.

- Downtime Tracking & RCA

- Track stoppage reasons, duration, cause, action taken, and prevention steps.

- QR Code Access for Technicians

- Scan any machine to view history, manuals, photos, and PMs instantly.

- Spare Parts & SMT Inventory

- Track nozzles, belts, sensors, motors, feeders, heaters, boards, and PLC components.

- Multi-Site Visibility

- Standardize maintenance across multiple electronic assembly sites and factories.

Features

Key Features Electronics Manufacturers Need

MaintBoard supports the full electronics manufacturing process—SMT, assembly, testing, utilities, and cleanrooms.

- SMT Line Maintenance

Maintain pick-and-place machines, feeders, conveyors, nozzles, vision units, and alignment systems.

- Reflow & Wave Solder Maintenance

Track heaters, fans, flux traps, conveyors, thermocouples, and temperature calibration.

- AOI & Testing Equipment

Manage calibration and PMs for AOI, ICT, FCT, flying probe testers, and measurement tools.

- Cleanroom & HVAC Systems

Maintain chillers, compressors, air shower units, filters, AHUs, and humidity controls.

- Spare Parts for Electronics

Track motors, belts, heaters, relays, sensors, pneumatics, and SMT consumables.

- Failure Analytics & Reports

Analyze repeat failures, MTTR, MTBF, SMT-specific downtime, and process bottlenecks.

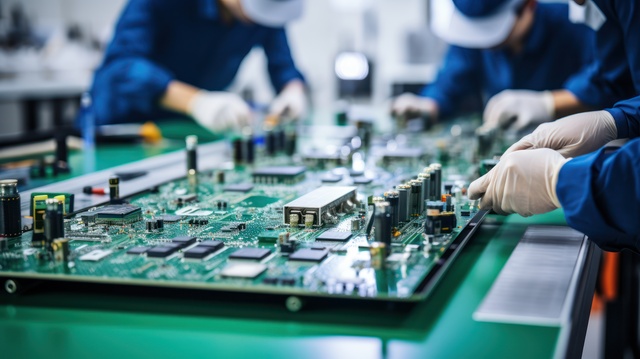

Where MaintBoard Fits in Electronics Manufacturing

MaintBoard supports every major area of electronics production—from PCB assembly to semiconductor back-end testing.

- SMT & PCB Assembly

- Maintain pick-and-place, reflow ovens, solder printers, conveyors, and feeders.

- EMS (Electronics Manufacturing Services)

- Track shared assets, testers, fixtures, utilities, and assembly lines.

- Consumer Electronics

- Manage assembly tools, conveyors, robotics, testers, and packaging systems.

- Semiconductor Back-End

- Support wafer testing, packaging, bonding, sorting, environmental chambers, and vacuum pumps.

- Electrical & Control Panel Assembly

- Track wiring stations, crimping tools, testers, compressors, and quality equipment.

- Cleanroom & Utilities

- Maintain HVAC, chillers, filters, vacuum pumps, nitrogen lines, and air handling systems.

Metrics

Impact of CMMS on Electronics Factory Reliability

Electronics plants using MaintBoard see measurable improvements in uptime, quality, and throughput.

15–30%

Reduction in SMT line stoppages

Better PM and real-time visibility reduce misfeeds, jams, and equipment faults.

20–40%

Faster troubleshooting

Technicians access manuals, photos, spares, and history instantly.

25–50%

Better audit readiness

Calibration, PMs, downtime, and documentation remain easily accessible.

Electronics Manufacturing Maintenance FAQs

- Can MaintBoard handle SMT, reflow, and AOI maintenance?

- Yes. MaintBoard fully supports maintenance for SMT lines, reflow ovens, wave solder, AOI, and testing benches.

- Does MaintBoard support semiconductor back-end plants?

- Yes. Plants use MaintBoard for bonding machines, testers, chambers, pumps, and calibration-heavy equipment.

- Can technicians use QR codes for quick access?

- Yes. QR codes allow technicians to view history, manuals, PMs, and spare parts instantly.

- Does MaintBoard help with calibration tracking?

- Absolutely. MaintBoard tracks calibration schedules, tolerance limits, certificates, and audit logs.

- Does MaintBoard support multi-site electronics factories?

- Yes. Standardize PM templates, failure codes, and reports across all sites.

Ready to Improve SMT Uptime and Reduce Production Delays?

See how MaintBoard helps electronics manufacturers standardize maintenance, eliminate bottlenecks, and improve line reliability.