MaintBoard Predictive Maintenance Software

Predictive Maintenance for Plants & Facilities

Predict failures early. Cut unplanned downtime.

MaintBoard uses meter readings, condition data, and trend alerts to detect issues early and prevent breakdowns.

Key Benefits

- Identify anomalies using meter and condition trends

- Reduce recurring failures and emergency breakdowns

- Trigger predictive work orders automatically

- Fast inspections and reporting via mobile

Problems Predictive Maintenance Solves

- Unplanned Breakdowns

- Unexpected failures stop production lines and force teams into emergency repairs.

- Missed Meter-Based Maintenance

- Manual tracking leads to early or late maintenance and unnecessary failures.

- No Visibility Into Asset Health

- Condition data buried in spreadsheets makes trend detection difficult.

- Repeated Failures

- Minor vibration or temperature spikes go unnoticed until failures repeat.

- High Maintenance Cost

- Reactive work increases overtime, emergency spare usage, and downtime.

- Weak Audit Traceability

- Meter logs and predictive checks are often incomplete or missing during audits.

Workflow

How MaintBoard Predicts Failures

MaintBoard shifts your maintenance from reactive to predictive using alerts, meters, and condition monitoring.

- Connect Equipment & Meters

- Add assets and configure meters such as running hours, cycles, or production counts.

- Set Predictive Triggers

- Define thresholds or trends that auto-generate work orders before failures occur.

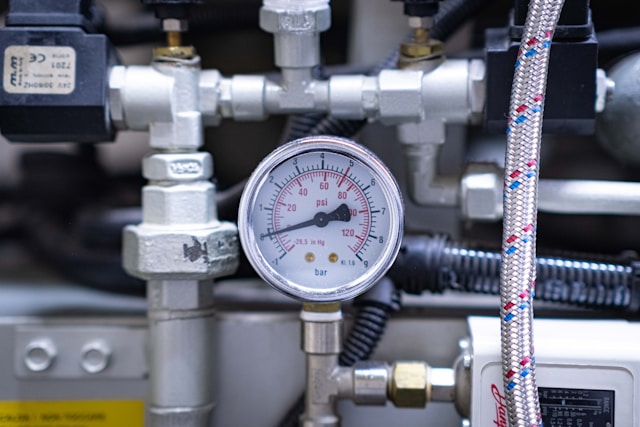

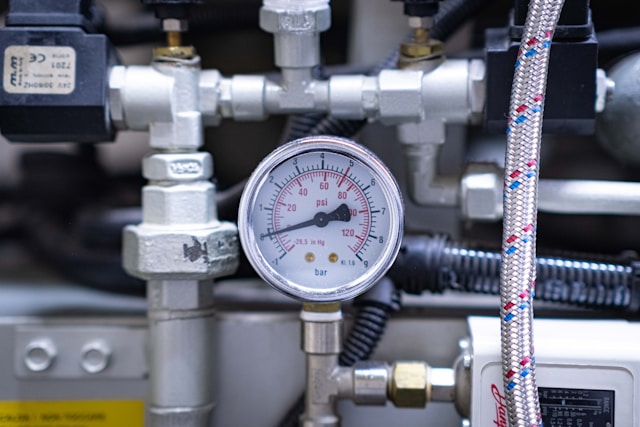

- Monitor Condition Data

- Track vibration, temperature, and pressure with real-time dashboards.

- Automate Work Orders

- Predictive tasks are created automatically—no manual monitoring required.

- Mobile Inspections

- Technicians capture condition readings and complete checks using mobile devices.

- Analytics & Reporting

- View degradation trends and asset health with clear visual reports.

- Audit Trail

- Full history of meter readings, predictive checks, and generated work orders.

- Integration Ready

- Connect with Industrial IoT, SCADA, OPC, and PLC systems for real-time data flow.

Features

Key Predictive Maintenance Features

MaintBoard delivers reliable, data-driven maintenance with features that prevent failures before they disrupt operations.

- Meter-Based Triggers

Auto-generate work orders based on running hours, cycles, or counts.

- Condition Monitoring

Track vibration, temperature, and pressure with real-time alerts.

- Automated Work Orders

Create predictive tasks automatically before failures escalate.

- Trend Analysis Dashboards

Visualize degradation patterns and long-term performance trends.

- Audit & Compliance

Maintain complete logs of predictive activities for audits.

- Mobile Inspections

Capture condition data and complete checks from any mobile device.

Trusted Across Industries

Plants and facilities use MaintBoard to reduce downtime, cut maintenance costs, and improve equipment reliability.

- Manufacturing Plants.

- Reduce line stoppages with predictive alerts on CNC machines, conveyors, presses, and robots.

- Facility Management.

- Predict HVAC, chiller, and elevator issues before they disrupt operations.

- Fleet & Transportation.

- Monitor engine parameters, hours, and wear indicators to plan maintenance during downtime.

- Process Industries.

- Track pump cycles, compressor hours, and valve conditions in chemical, food, and pharma plants.

- Commercial Buildings.

- Maintain generators, chillers, and other critical building assets with predictive triggers.

- Equipment OEMs.

- Offer remote predictive monitoring and automated alerts to your customers.

Metrics

Maintenance Metrics Transformed

Predictive maintenance improves reliability and reduces maintenance costs across key KPIs.

60–80%

Reduction in unplanned downtime

Early alerts prevent failures and avoid production loss.

40–60%

Faster mean time to repair

Smaller issues detected early require less repair time.

25–40%

Lower maintenance costs

Reduced emergency work, less overtime, better spare planning.

Predictive Maintenance FAQs

- How does predictive maintenance differ from preventive maintenance?

- Preventive follows a schedule. Predictive uses meter and condition data to perform maintenance only when needed.

- What types of equipment can benefit from predictive maintenance?

- Any equipment with measurable hours, cycles, vibration, temperature, or pressure values.

- How long does it take to implement MaintBoard?

- Most plants onboard in 2–4 weeks with asset setup, meter configuration, and training.

- Can MaintBoard integrate with our existing CMMS or ERP?

- Yes. MaintBoard provides APIs to sync work orders and asset data with major CMMS and ERP platforms.

- What kind of training do you provide?

- Onboarding, live training, documentation, videos, and ongoing support.

- How do you ensure data security and compliance?

- MaintBoard uses encryption, access controls, audit logs, and offers cloud or on-premise deployment.

Transform Your Maintenance Strategy

Move from reactive to predictive maintenance and improve uptime while cutting costs.